Search the Community

Showing results for tags 'doric'.

-

I recently discovered and serviced a Wahl Eversharp Doric in Kashmir pattern. The pen is missing a cap. It’s clearly a first generation Doric but I don’t know what size it is. It measures about 11.5cm from nib to barrel end and 10cm without the nib. Here is a size comparison to a WE Doric Coronet in Cathay Green. Its section threads actually go with the Cathay cap but the cap is a little too short for the Kashmir. I know it’s a long shot but I will try to find a cap for it. If not, I will have to sell the pen as parts though it’s now serviced and ready to write. The WE FLEXIBLE nib is very nice so I’d rather find a cap for it. Thank you for your help!

-

I wanted to share with you the repair of a a crumbled barrel end of a gorgeous oversize Wahl Eversharp Doric in cathay color. A soon as I get this pen (50$) I had the bad idea to push a little on the crumbled crown from the barrel end and boom, it broke up in pieces... Here is the initial state... I cleaned the end barrel removing all the crumbled celluloid. I decided to rebuild the Barrel end crown using another broken doric cap in cathay color (junior size) (also crumbled at the end): here is this cap (yellow arrow shows instable cracks, I got it on ebay for 30$): I first removed all the "unhealthy celluloid" (broken or crumbled parts) from the broken doric cap. I then used sand paper to remove the discolored superficial layer of the cap. Here is what remained of the cap: Then the barrel was split in half using a fine jeweler's saw and sawn the splited barrel in "tiles" of the width of the barrel end: here are the tiles: Then the tiles were flattened and glued together using acetone welding. You must immerge a short time each tiles in acetone to allow them to soften. The tiles are then ready to be assembled two by two by pressing them against each other. On the left of the picture you can see tiles already assembled and on the right a fresh one ready to be soaked in acetone and welded to the other ones. You then get a kind of celluloid dice formed by successive acetone welded layers: And now the hardest part!: you have to wait for 3 months to allow the dice to dry (to shrink). It's now time to acetone weld the dice onto the end barrel: Then the crown is sculpted, sanded it down to the 12 lateral facets of the doric barrel with rough sand paper. To guide you and to avoid damaging the lateral facets of the barrel you have to protect each facet with a piece of metal taped with double sided scotch tape onto the barrel facet: Here is the rough result on the left (without fine sanding) and with fine sanding on the right (up to 5000 grit sandpaper): When you have finished with sculpting the 12 lateral facets it's time to sculpt the crown (end side). You have to sand it using a metallic guide taped with regular tape on the lateral facets: After finishing and sanding using Micromesh (grit 8000/12000) here is the result: The pen after a year of use didn't show any signs of crumbling, there was no celluloid shrinkage either:

-

I got lucky in an eBay auction yesterday: a Doric ringtop in Kashmir. The condition seems decent, and I'll replace the Manifold nib with sliderless Adjustable nib that I stripped from the corpse of a ruined pen. You might call the nib ruined, but I call them paintbrush-flexy. When I get the thing I'll post some pictures.

- 13 replies

-

- wahl-eversharp

- doric

-

(and 1 more)

Tagged with:

-

Hello, this is Victor. I recently received a cathat doric without cap. Is there any one has the cap to sell me? size is standard. I want to make it perfect Lol. Email is zelinwang222@gmail.com fell free to PM me or just email me if you have one. I appreciate that.

-

1. Does #3, #5, #10 adjustable nib only equipped on the first generation dorics? 2. Are there any adjustable nib that with the solid silver slider has the same size as #6 and #9? 3. Every adjustable nib should be together with ink shut off device when they are at factory condition, right? 4. Why the semitransparent segments on doric's barrel have different length in second generation standard dorics? (see pictures) 5. Except adjustable nibs, which nibs are considered to be the original nibs of Doric? 6. Does the second generation standard Doric's barrel have the same length as the Oversized one? 7. Which generation dorics are more collectable?

-

Hi all, this has to be the right forum to ask this question so I really hope to get some useful input. I've recently bought this Wahl Eversharp Doric 2nd generation, senior saphhire blue with no.9 adjustable nib and a shut off valve in tip top condition. It has its filling mechanism repaired by a renowned pen restorer very recently. The pen burps. I am trying to pin point the source of the problem. One thought is the obvious: there is a leak somewhere. Another is the possibility that ink remaining in the feed during filling, drops down eventually. Another possibility is that the pen is just like that. I wouldn't know because this is my only Doric. Another possibility is that the nib and feed aren't positioned properly. I cannot personally eliminate the first option. When I got in touch with the pen restorer, I got a very rude response and he was refusing to even consider the possibility or the need to look at the pen and even blocked me. You don't block someone with an item you're warranting. So I'm on my own for a while until I am able to get back in touch, but I need ideas as the problem could be somewhere else anyway. To eliminate the 2nd possibility, I cleaned up the nib and really well with a tissue draining most/all excess ink that could make the feed wet or saturated at all. I got good behaviour for a short while and put the pen to one side. The next day I picked it up, still with good behaviour, but the fluid is slowly starting to show accumulating under the nib. Total writing time is less than 5 minutes for both days. Third and fourth possibilities, I'll need your help with. Do Dorics burp naturally? Any ideas what it might be? What can I do at home to troubleshoot and try out where the leak is from? I have repaired pens and mechanisms myself, but I am not willing to even touch this pen with any attempt at disassembly long as there is a warranty on that repair. I hope someone can help me out get this pen figure out. It has been a very meaningful purchase to mark the end of a very exhausting 7 year journey, and I still haven't been able to use it or enjoy it, and even starting to feel I've been screwed (given the bad attitude coming from the repairer who was basically just being full of himself and his impeccable repairs).

-

-

Hey everyone, sorry to bother this sub with an unpolite how much is worth it kind of post but I would like to rehome this pen since it deserves to be used and appreciated. The pen is (I believe) a Wahl eversharp Doric Morocco, standard size fitted with a new sac, unluckily the sled it's missing and thatì's the only issue with the pen. https://www.dropbox.com/sh/jpav1bw4z7xydwy/AADqcnVYE-qkny1xpasBQDf-a?dl=0 what would be a fair price? thanks in advance

-

Here is a tutorial on how to repair a pen I love: Wahl Eversharp Doric Second generation with plunger Filler. Hope this could help the aficionados... And please forgive my bad English... Properties of the filling system: The filling system looks like early Onoto's: it is kind of "reverse syringe" called the "one shot vacuum filler" by Eversharp. To fill the pen you have to pull the piston syringe, then dip the pen in ink and finally push the piston: it fills with ink. When you push the piston, a vacuum is created behind the piston which is released as the piston comes close to the proximal end of the barrel which is larger. Anatomy of the pen (according to Eversharp's patents) : 1: Disk nut 2: Plunger disc 3: Plunger rod 4: Rubber plunger Washer #1 5: Cork plunger Washer 6: Rubber plunger Washer #2 7: Lock nut 8: Nib 9: Feed 10: Section 11: Section pin 12: Barrel 13: Barrel brushing (AKA "packing unit") 14: Banded sleeve 15: Barrel end ("piston button") Initial cosmetic aspect of the pen: Here is a second generation oversize doric with desirable garnet shell color, adjustable nib and plunger filler, unfortunately without the ink shut off device... Two main cosmetic problems for this pen: a dent on the section and some irregular aspects of the facets. First part: pen disassembly: A. Piston button unscrew: To unscrew the piston button, first twist the piston button counterclockwise to pull the plunger rod, then with a pair of pliers hold firmly the lock nut and unscrew the piston button counterclockwise. One important thing here: you have to note where exactly the lock nut is on the plunger rod to put it in the same place for re-assembly: if you don't do so you may experience ink flow problems of filling problems at the end of the repair. Then unscrew the lock nut. B.Banded sleeve removal: The banded sleeve is press fit onto the packing unit. To remove the banded sleeve I first use a thin scalpel blade between the barrel and the banded sleeve and carefully move my hand right to left to loosen the banded sleeve. Then when you manage to create a small gap between the banded sleeve and the barrel do the same thing with a thicker and stronger blade to farther loosen the banded sleeve. Sometimes the banded sleeve is too tight and you have to use heat to loosen it (see below on how to use heat with Eversharp's celluloids). C. Packing unit unscrewing: This is for me the most feared, most time consuming, and most critical step. Not done properly you can ruin the pen forever. Always remember that Packing unit unscrews CLOCKWISE!!! Be very, very patient: It usually takes one hour to unscrew, in my experience I almost spent a day unscrewing this pen part! The key to the success is to use heat, the aim of using heat is to soften the shellac used to seal the packing unit onto the barrel. You will have to heat and cool the barrel end up to 20 times (sometimes) to unscrew the packing unit. Always use dry heat (using boiled water will make a celluloid hydrolysis and ruin the pen), never use open flame as celluloid is a furiously flammable material. I personally use a machine used to bend glasses frames, but the most common tool used is a heat gun (ideally with a variable thermostat). On the other hand heating can bend or burn celluloid: to avoid this pitfall you must always keep an eye on the celluloid you are heating. A good trick is to use a sharp pool and to push it against the heated celluloid: as soon as the celluloid starts to melt the tool starts to sink in the celluloid: this is a good alert to stop heating and to wait the celluloid to cool. NEVER try anything (like unscrewing the packing unit) when the celluloid is hot: you will bent it forever. You must protect the rest of the pen from heat: I use a sheet of paper I wrap around the pen, and only let the part I want to heat unprotected. D. Nib section unscrewing: The section unscrews counterclockwise. You have to use heat to unscrew (Cf C.). If you use heat, you don't have to use players to grab the section and the barrel (scratching it...) to unscrew, fingers are sufficient!. E. Section disassembly: First you have to get the section pin out of the section: use a needle to push the pin. On the picture the pin is broken: you will have to make another one after... Then rock the nib and feed assembly out of the section, not by pulling it but pushing it from the section back end with a flat ended cylindrical tool (nail punch) and a hammer onto a nib block (Cf picture). If the feed and nib are stuck into the section, soaking the whole section overnight in water can help. F. Disk and Disk nut disassembly: Get the plunger rod out of the pen from where the section screws on the barrel. Use pliers to grab the disk nut and unscrew it counterclockwise, using heat can help (Cf C.). Get rid of the plunger disk remnants. G. Cap disassembly: Disassembling the clip from the cap seem to be a good idea but is impossible on second generation doric (unlike first generation where the clip can be disassembled by removing the inner cap) Second Part: Cleaning and Polishing: A. Barrel and cap cleaning and polishing: Dorics are faceted pens, traditional methods of polishing (machine polishing with discs for example) are not suitable as it would ruin the facets and make the pen round. Faceting the barrel seems to be a better option. I grind each facet of the pen with sandpaper, progressively increasing the grit of the sand paper: I start at 800 grit, then 2000 grit, and end at 5000 grit: the result is a high gloss facet with a nice geometric barrel. For each facet I put the sandpaper onto a flat surface (like a mirror) and rub the facet against this flat surface making movements from the end of the barrel to the tip of the barrel (I never do any rear movements from left to right). I decide to increase the grit only when the surface of the facet is evenly flat and ground. The inner surface of the barrel can be cleaned with a soft cloth with a mix of 50% domestic ammonia and water (use gloves it dissolves inks but also skin!). NEVER use steel wool on the inner surface to the barrel as it could scratch it and damage the filling system. You can do the same for the cap, but always protect the gold plated ornaments (clip and cap band) as polishing could damage them. To protect the ornaments simply wrap tape around them. Never try to polish the facet where are the cap imprints ("Wahl Eversharp made in USA") it will definitively erase them. B. Packing unit and screw thread cleaning: Using a kind of torn pin expel the old plunger washer (see on picture). Then clean the threads of the section, the threads of the barrel (at both ends), the threads of the packing unit: clean the remnants of the sealing material which are in the threads. You can use the torn pin to put it into the threads to clean them. C. Rest of the cleaning: Cleaning nib and feed can be done using a mix of 50% domestic ammonia and 50% water: soak the nib and feed for 30 minutes then use a tooth brush to clean the feed channels. Cleaning the cap can be done using the same mixture and a clean cloth put into the cap, but do not soak the cap into the ammonia solution as it could destroy the gold platting of the clip and cap band. Polishing the gold nib and the gold ornaments can be done using a clean cloth and polishing-cleaning solutions (Mirror etc...) Third Part: Re-creating the missing parts: A. Cork plunger washer turning: To re-create the cork plunger washer I use The cork sheets which are glued to the bottom of champagne corks (it is a very good quality cork with few holes for a good seal). Use a cutter blade to separate the cork sheet from the champagne cork then flatten both ends of this sheet with sand paper (600 grit is ok). Use a punch of a diameter above the inner diameter of the packing unit to cut a small disc. Drill a hole in the center of the disc with a thin drillbit (the diameter of the drillbit must be inferior than the diameter of the plunger rod to provide good seal. Then finally fine tune the external diameter of the disk twisting it against sand paper (600 grit). The disk should be pressfit into the packing unit. B. Rubber plunger washer turning: Two or three (depending on the packing unit depth) rubber plunger washers are generally used to provide a good seal. To recreate them I use a rubber sheet (bought on Ebay) of around 1mm thickness. I cut small disks of rubber using a punch with a diameter just above the inner diameter of the packing unit. Then I drill a hole in the center of the disk just below the diameter of the plunger rod. To fine tune the external diameter of the rubber disk I set it on the drill bit and make the drill turn with the disk set on it against sandpaper (600 grit). The disk should be pressfit into the packing unit. C. Plunger disk re-creating and fine tuning: Cut a rubber disk with a punch with a diameter just above the size of the inner diameter of the barrel. Cut with a punch, or drill a hole in the center of the disk (around 2mm diameter). Set the disk onto the plunger rod screwing the disk nut clockwise (you sometimes need shellac to lock the nut onto the plunger rod) until it is blocked onto the plunger rod and then fine tune it setting the plunger rod on a drill (Dremel for example). Fine tuning the plunger disk is the second most delicate step for repairing the pen (see second pic). The rubber disk should not be too large nor too small otherwise vacuum cannot be created in the barrel. To know wether the disk is too small or too large, put the plunger rod with plunger disk in place into the barrel, then push the plunger rod and watch the plunger disk through the ink window: if the disk slightly bents upwards: it is good, but if it stays bent downward it is too large. Then pull the plunger rod and watch again the plunger disk through the ink window: if it stays flat the plunger disk is too small, if it bents downward the plunger disk could be of a good size or too large. D. Section pin re-creating: I use a stainless steel rod to re-create the section pin: I use a disk sander to decrease the diameter of the rod, polish it with sandpaper, ad cut it to the size of the native section pin. I then place it into the section pushing it with a needle. The pin should not be too large otherwise there is a risk to destroy the barrel end threads. Fourth part: Re-assembly: A. Barrel reassembly: Put the plunger rod with the plunger disc in place into the barrel, put allot of silicone grease onto the cork and plunger washers, put the plunger rod through the washers, set the washers into the packing unit, put silicone grease on the packing unit threads, screw the packing unit counterclockwise until it stops, set the banded sleeve on the packing unit end (some of the packing unit must protrude through the banded sleeve). B. Piston button reassembly: Screw the locknut clockwise on the plunger rod and set it at the same place that it was before disassembly. Screw the piston button clockwise on the plunger rod and tighten it holding the locknut with a pair of pliers. C. Section reassembly: Put the nib on the feed at the exact position it was before disassembly (some marks can be seen on the feed). Holding the nib-feed between two fingers press-fit it into the section at the same position it was before disassembly. Then put some silicone grease into the threads of the section and screw it clockwise into the barrel. Fifth part: conclusion and troubleshooting: With this method Dorics can fill up to 80% barrel capacity (back to factory standards). If the pen does not sucks ink, many problems can be encountered: proceed as follows: - First the packing unit is not airtight: unscrew section and piston button and lock nut, then insert the plunger rod into the back of the pen, with your mouth "suck" the "section end" of the barrel, if the barrel stands sticked on your tongue or lips the packing unit is airtight. If not fine tune the washers or add another rubber washer in the packing unit or put more silicone grease. - Second the plunger disc is not airtight: put the plunger back in place (through the "section end of the pen") pull the plunger rod and push it slowly downward it you ear a "pop!" it is airtight, if not fine tune the plunger disk again. If the pen is too wet writer proceed as follows: - First: repeat the first operation for "pens does not sucks ink" and wait a long time the pen sticked on your lips: if vacuum breaks there could be a subtle air breach in the packing unit. - Second: it could be a nib/feed problem (check elsewhere on the forum). If you cannot pull the piston the the end of the barrel: It seems that the plunger disc is too large: fine tune it again!! Thanks you, hope it will help Doric lovers. If you need any advice on how to repair a broken doric adjustable nib slider please check: https://www.fountainpennetwork.com/forum/topic/316447-wahl-eversharp-adjustable-nib-slider-repair-technique/

-

Parker Vacumatic (Faceted!), I Hadn't Get Any Information About It.

JorgeLpzLmg posted a topic in Fountain & Dip Pens - First Stop

Hi!! Two days ago I bougth at Mexico city (where I live) a faceted fountain pen, wich looks as a Parker Vacumatic oversize. I was searching in the web in orden to confirm if it is an authentic Parker, but I didn't get any information or images about faceted Parkers. The pen description is: Barrel engraved: "Parker Vacumatic USA" (the "V" is engraved on the "R") Long with cap: 13.5 centimeters (5 1/4") Barrel diameter: 1.6 centimeters (5/8") Color: Borgoña Faceted barrel and cap Apparently, the original nib was replaced with a "Harley Davidson" nib (!!!). Can you help me to confirm if it is an authentic Parker? If it's an authentic pen, what is the correct nib for it? I'm attaching some pictures. Thanks! Jorge. -

The first hour was spent trying to get the lever and slotted piece that goes into the bottom of the barrel to stay together while trying to insert both at once. Then I found a work around online which ended up working on the second try and in less than 5 minutes.

-

Some photos of the nice pen

- 7 replies

-

- wahl eversharp

- doric

-

(and 1 more)

Tagged with:

-

Wahl-Eversharp Doric (2Nd Gen.) - In Need Of Repair Advice

beardedpens posted a topic in Wahl-Eversharp

Hello Everyone, I finally created an account today after browsing these forums for the last few years. I am new to vintage pens, but not fountain pens in general. I often go to antique stores to pick up older pens, and can complete simple restorations. In this case I believe I have met my match. I found this Doric for $20.00 at a local antique shop. Since then I have done a simple cleaning of the pen, and was able to free the plunger, along with the adjustment slider. The nib is very whet, and uber flexible... but is as sharp as a knife. The second issue is that the seals seem to have given out, and it refuses to drawing ink. The internal mechanism seems to be beyond my repair expertise, and at this point I don't want to damage the pen because the body is in almost perfect condition. Who should I go to that could repair this pen? I'm a student and don't have hundreds of dollars to spend on this, but at the same time I don't want to break the pen of my dreams. Images (Not sure if this is how i'm supposed to do this)- 24 replies

-

- wahl-eversharp

- doric

-

(and 1 more)

Tagged with:

-

I have a Doric ringtop arriving today: junior-size, named "Tootie". The pen looks in nice shape but the nib is described as a bit of a mess. Of course I'd like an Adjustable nib (a #3 to #5), but what else would fit in such an instrument?

-

So, I bought this in an online auction a couple weeks ago. Knew it wasn't mint, but upon receiving and inspecting realized quickly that it was on the lower end of user grade instead of "Good" as described. I had intended to flip it, but now am unsure whether that's worthwhile. So the question: To what grade could professional restoration return this pen? I have about $175 in it at the moment, but really have no idea what it's worth in this state and whether restoration would increase it's worth enough to consider selling it. It's a pleasant pen, and the nib is really a lovely writer, but I hadn't really intended on keeping it. What would you do? Any thoughts/suggestions are much appreciated. Burma color isn't bad. Has some nice variation. Deep scratch in the cap. Brassing of the medallion (and other trim as well). Crack in the cap where (it appears) the material is degrading. Runs about 1/3 around the cap. Hairline crack seems stable, doesn't go past cap band. EDITED: to add a picture.

-

Somehow i'm came in possess of a Wahl Eversharp Doric Junior for 10€ plus shipping costs - with a parker 51 and a nice waterman's in the same lot It's in really good shape and i want to service it - i can ear the sound of a shattered sac from the inside - but i know almost nothing about it's construction - is my first Eversharp too - so i've some questions for someone more expert than me: - is the section friction fit? - the lever seems to be blocked by the oxided sac but if it will not be so, what type of lever/pressure-bar system i'll need to repair? - the nib/feed unity seems to be ok - a "flexible" marked nib with long tines - but i've read the nib is screwed in in the section. is it true? plus, if someone have any other advices, feel free to point me in the right direction!

-

Hello everyone, I recently picked up an absolutely mint W-E Doric desk pen (in Cashmere, of all places) and was wondering what the correct sac size for it was. It has a #5 adjustable nib and the nipple appears to be slightly more than 1/4" across. I've seen conflicting info from several sources on which size sac to use: Richard Binder's website cites the proper size as 17 or 18 (not quite sure if my pen qualifies as a Doric or a Personal Point) while some other sites give the proper size as 22 (which seems way too big). On a similar note, should I use a regular latex sac or a silicone sac to protect the celluloid (it's a grey-black color and I am unsure if it is prone to discoloration)? Thanks for the help!

- 8 replies

-

- wahl eversharp

- sac

-

(and 2 more)

Tagged with:

-

I've got a few adjustable nib Dorics, and tonight I was restoring another one when I started to wonder just how many adjustable nib sizes there are. I have a #3, #5, #7, and #9 in my collection, and I know there are also #6 and #10 nibs, but a search for ads and pictures already online only confirmed those. Were there are any #1, #2, #4, or #8 adjustable nibs? Thanks!

- 7 replies

-

- doric

- adjustable nibs

-

(and 1 more)

Tagged with:

-

So I bought a Gold Seal Doric ringtop in Morocco, but I don't like the nib: a rigid Skyline. I've gone looking around for a new nib, and what happened but I found another Doric ringtop (black...very pretty) for about the same money as the previous one, only with a flexier nib. Of course I bought it, because I am a madwoman. I already have a Doric with a clip in Kashmir, so this means I have a collection...this is probably not a good thing. But I still want another nib for the Morocco.

-

Hi ladies & gentlemen! I have a adjustable nib from a Doric but it hasn´t have the trim piece that adjust the wide. Recently I found (waiting it from mail) a broken nib adjustable. It is possibly put the trim from the broken nib to the other nib?? Thanks and excuse my poor school english. Rodrigo

- 1 reply

-

- wahl eversharp

- adjustable nib

-

(and 2 more)

Tagged with:

-

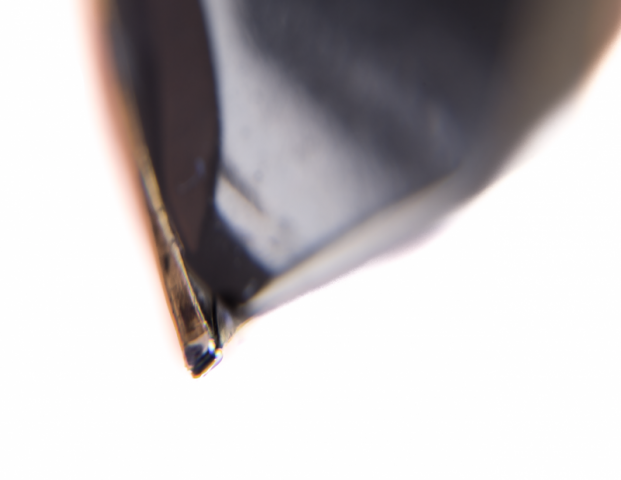

Hi Gang, Just a quick question about knocking an Eversharp Adjustable nib out of its section (or collar). The nib in question is on its way to me as part of a Doric Gold Seal 2nd generation parts pen. I think that the nib is a larger size Mk. 2 nib that could be equivalent in size to a Mk. 1 #9 nib. It doesn’t have the Airliner ink valve and so it’s either a personal point nib (as per original), or it’s been modified at some point in 80+ years, at this point I don’t know but it doesn’t really affect my question. Over the years I’ve knocked out a few nib-&-feeds and I’ve found that as the feed knocks out, the nib itself stays put meaning that the feed slides over the nib and tip. Perhaps I'm doing it wrong, but that's what seems to happen. For a traditional nib this isn’t really a problem, but I’m concerned that I may break the back of the nib slider and/or damage the feed as I knock it out if the nib doesn’t move with the feed, if that makes sense. Is this likely to occur, or am I over thinking it? Has anyone else experienced the feed moving but not the nib when knocking the pair out, or am I just doing it wrong? Anyway, here are a couple of pictures of the nib and any advice that you could give me would be very much appreciated. Cheers & Thanks Noel aka DuckMcF Melbourne, Australia

-

I have a beautiful Doric pen that I would like to eventually sell but it has a lever that won't budge, and an internal rattle. I'm guessing it needs a new sac. Does anyone have a step by step for taking the pen apart and replacing the sac or can you recommend a good repair person? See photo below of pen.

- 2 replies

-

- wahl-eversharp

- eversharp

-

(and 3 more)

Tagged with:

-

It took me some time to figure out what someone over on the Reddit fountain pen forum was using. All I saw was a close-up of the nib of his fountain pen. Turns out it was an adjustable nib on an Wahl-Eversharp. I found several on ebay and managed to snag it today. Is it shallow to say that this is the first pen I ever purchased for the looks alone? I normally buy Esterbrooks or vintage Waterman pens. Can you tell me if the adjustable nib was used on any other Wahl-Eversharp or is it unique to the Dorics? And one last thing, I am assuming this might need a restored (or at least an ink sac replacement). Are there any issues I should be aware of (peculiar to the model)...I mean-is it better to send of for restoration or attempt at home? I have such a crush on this pen that I don't want to mess it up. Thank you in advance for any advice. Here are some pictures of the pen.

-

I got these both recently but they have issues. The Equi-poised pressure bar is not attached to the lever, is there a way to re-attach it? The Doric has a crack running through the body's ink window and the threads. The inner section is undamaged, do you think it would be possible to have someone seal the crack? Sorry if this should be in the repair forum but I figured this was a better place to ask. http://i.imgur.com/KLle6rSl.jpghttp://i.imgur.com/thMxhQRl.jpghttp://i.imgur.com/5WaAcxLl.jpg Thanks!

-

The Wilson Aerofil And The Mhatre Doric, Skyline Clones From India

hari317 posted a topic in Fountain Pen Reviews

Further to my review of the Skyline homage by Gama here: link I decided to document the other Skyline clones in my collection. Mhatre pens and plastics and Wilson pen are long defunct companies. Here are two examples from these two companies. The photos are self explanatory. Mhatre was the manufacturer of the Indian TTK-Mabie Todd and Co. Swan, Indian Waterman's, and their own house brands Plato, Clipper, Writer, Doric etc. I suspect Mhatre had access to or was in some sort of tie up with Eversharp since they used the name Doric etc and even the feeders are very similar to the eversharp ones. Mhatre also made a clipper pen similar to the Eversharp 5th avenue pens. Follow the links to read the previously documented models. http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0068.jpg http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0069.jpg http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0071.jpg http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0072.jpg http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0074.jpg http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0073.jpg http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0075.jpg http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0076.jpg Even the feeder : http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0077.jpg http://i1269.photobucket.com/albums/jj582/hari-317/IndianSkylineClones/IMG_0078.jpg Cheers! Hari- 16 replies

-

- syline clones

- mhatre pens and plastics

-

(and 2 more)

Tagged with: