Those Special Tools

-

Forum Statistics

352.7k

Total Topics4.6m

Total Posts -

Member Statistics

125,731

Total Members2,522

Most OnlineNewest Member

KarenSkind

Joined -

Images

-

Albums

-

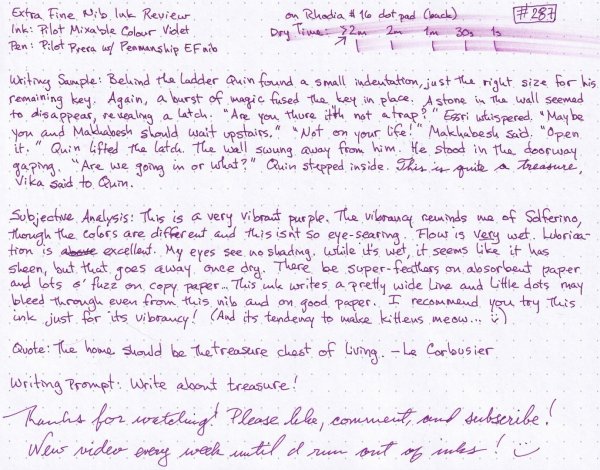

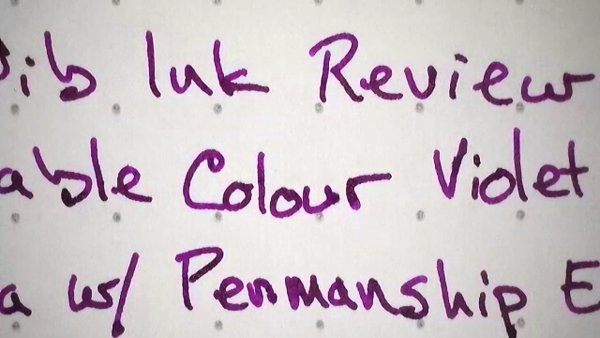

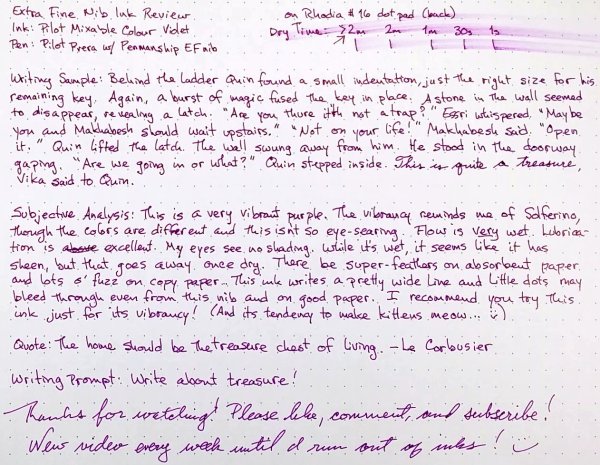

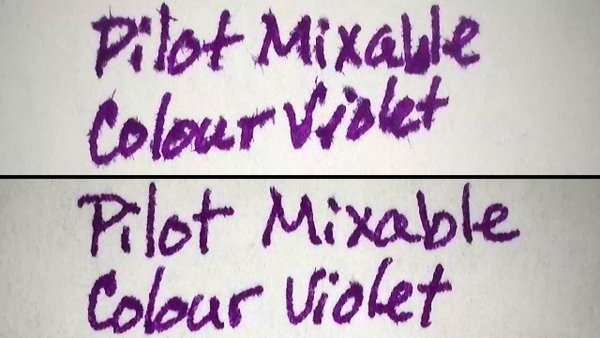

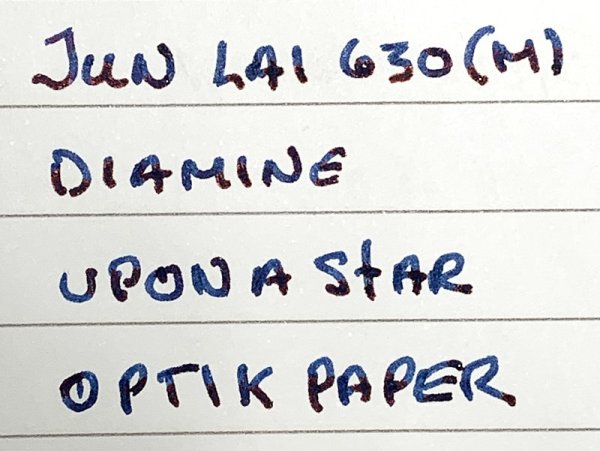

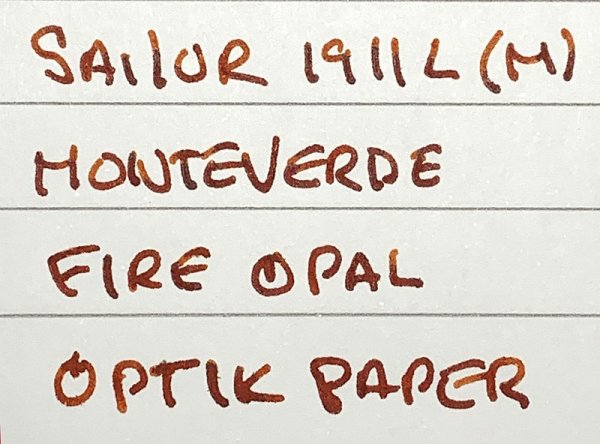

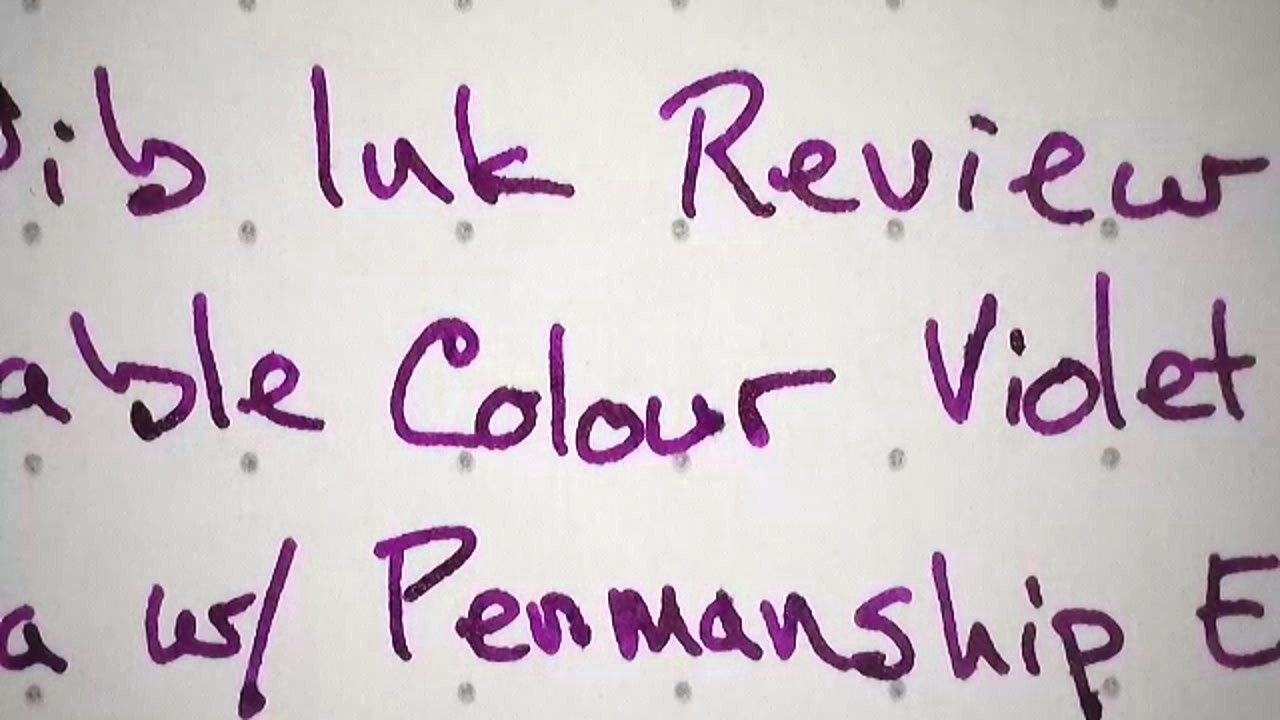

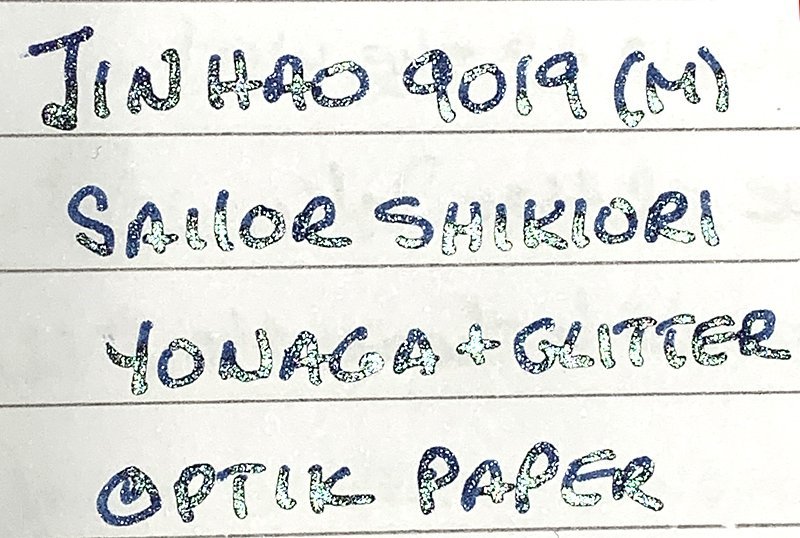

Extra Fine Nib Ink Reviews (17 of n)

- By LizEF,

- 0

- 57

- 57

-

USG 1

- By USG,

- 0

- 0

- 24

-

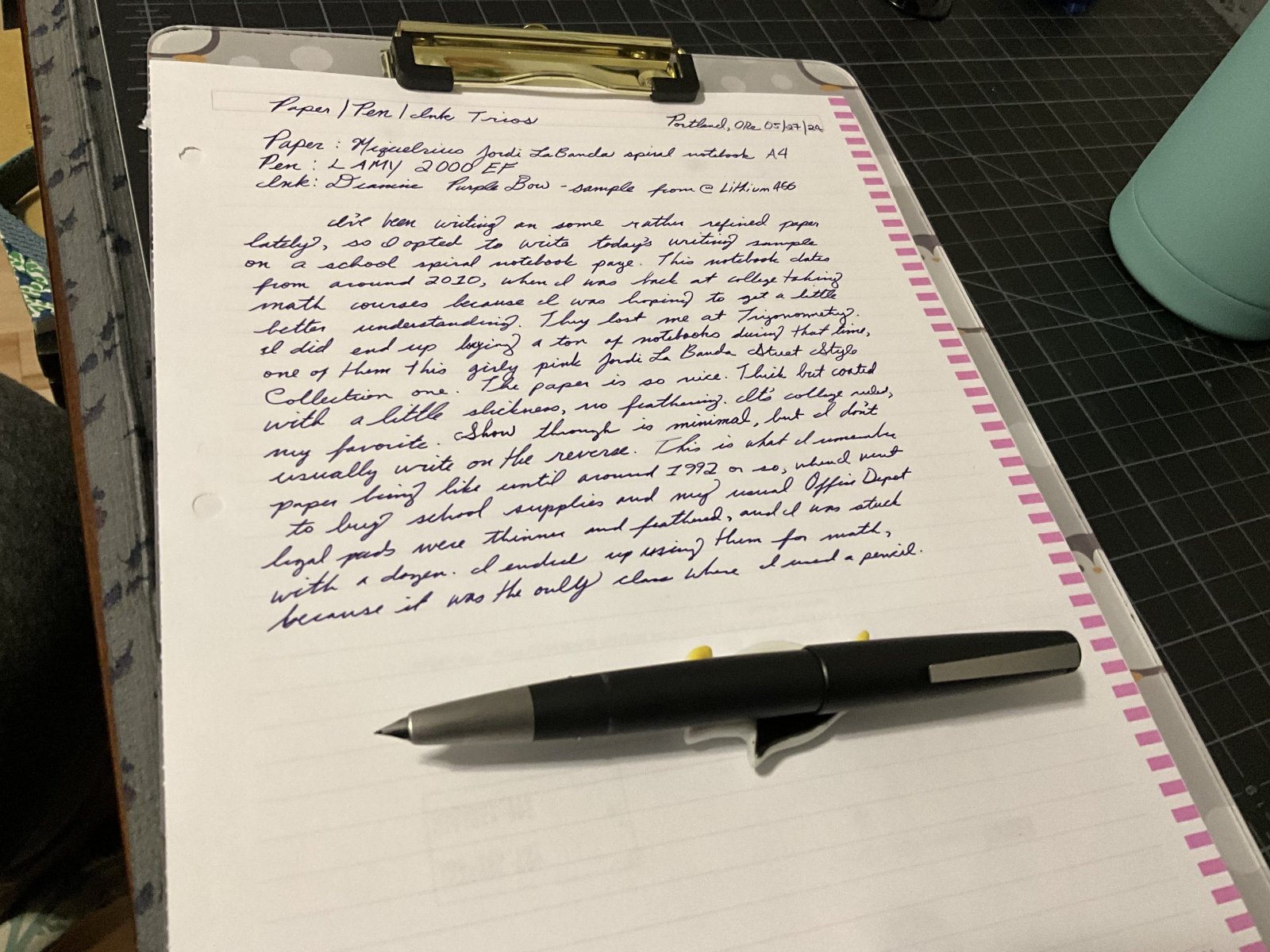

Trios

- By Penguincollector,

- 0

- 0

- 47

-

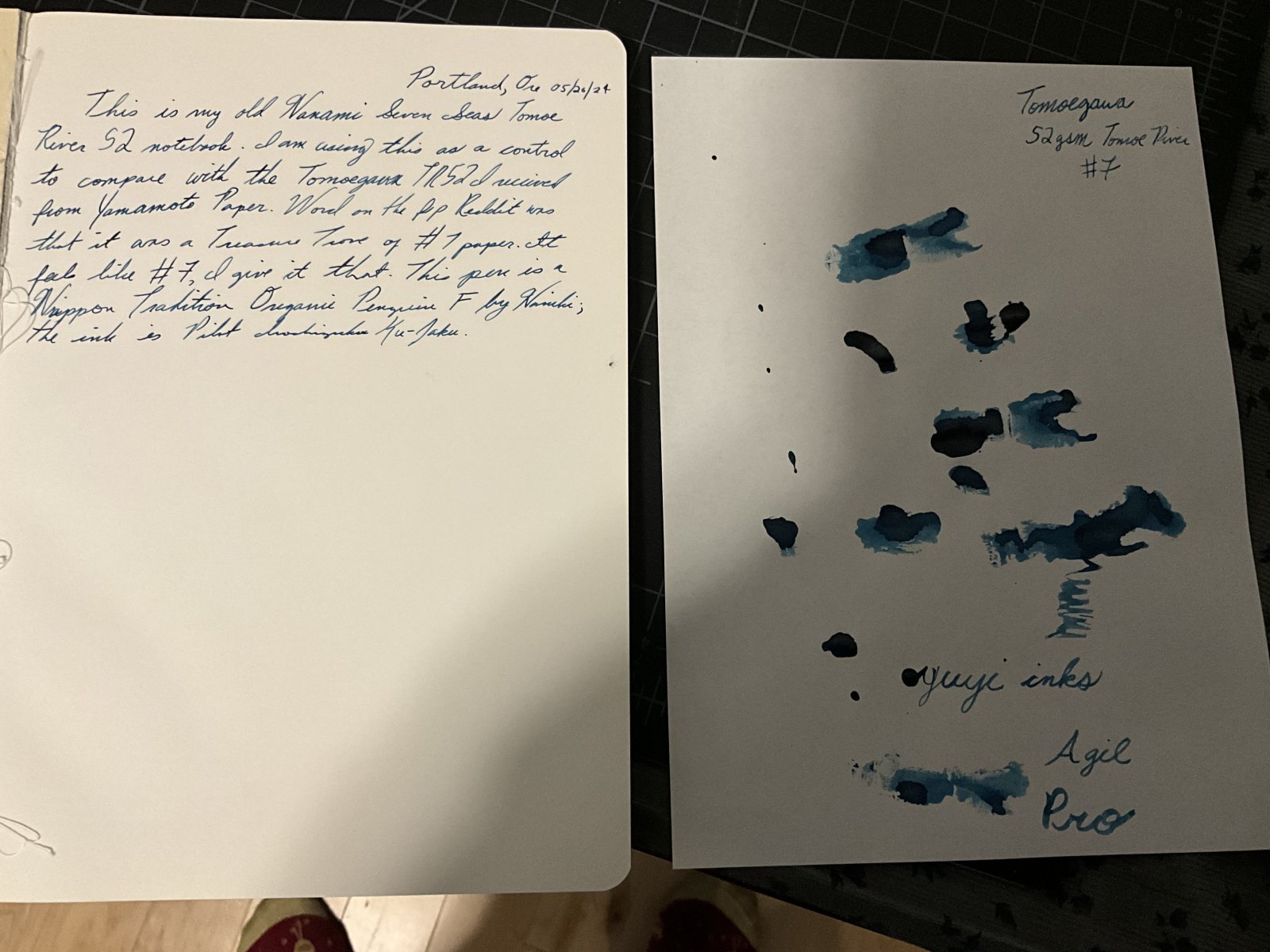

Ink testing pages

- By Penguincollector,

- 0

- 0

- 59

-

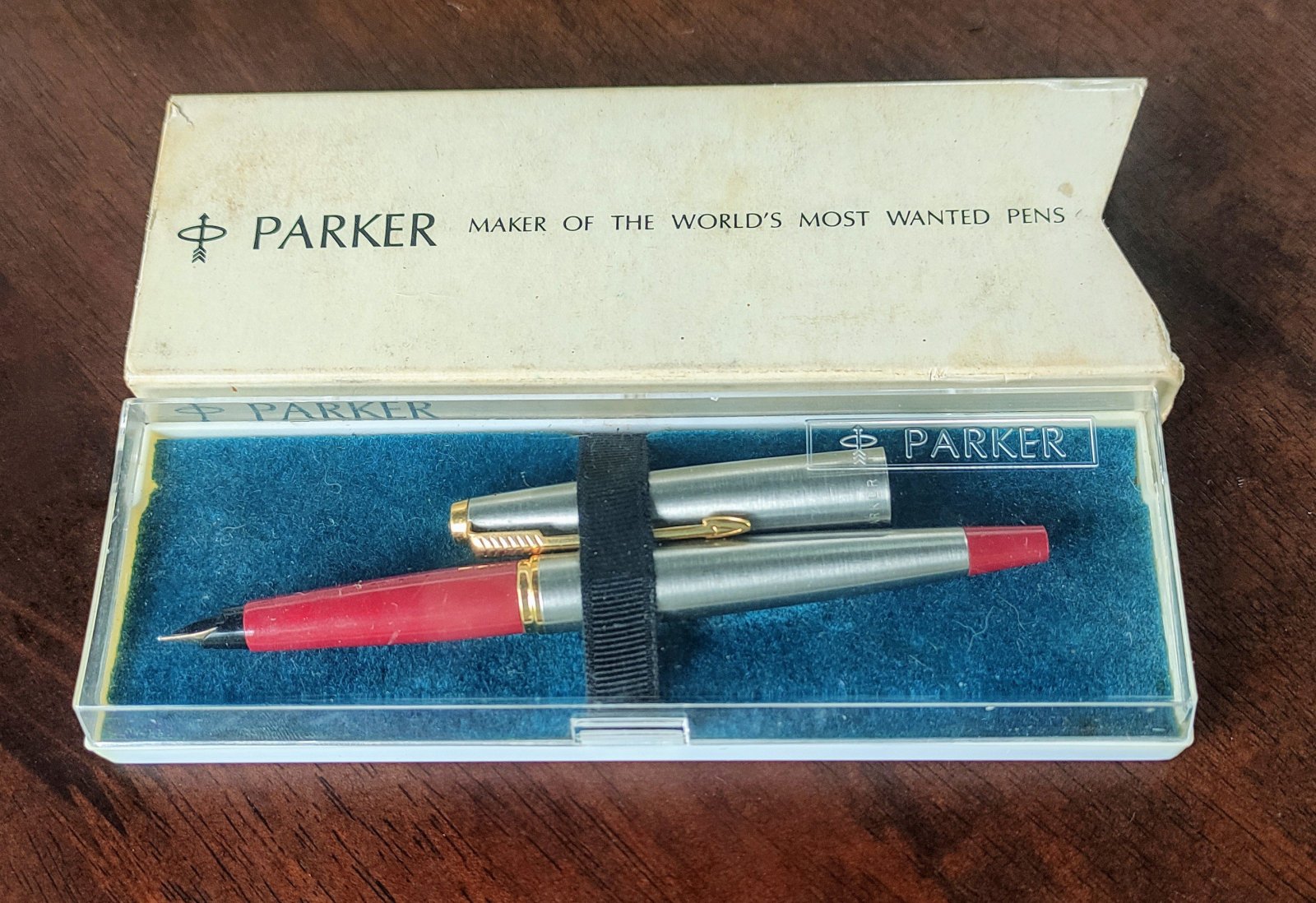

Various 2

- By PithyProlix,

- 0

- 0

- 11

-

.thumb.jpg.f07fa8de82f3c2bce9737ae64fbca314.jpg)

desaturated.thumb.gif.5cb70ef1e977aa313d11eea3616aba7d.gif)

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now