-

Forum Statistics

352.3k

Total Topics4.6m

Total Posts -

Member Statistics

125,526

Total Members2,359

Most OnlineNewest Member

marioullis

Joined -

Images

-

Albums

-

March- April -2024

- By yazeh,

- 0

- 0

- 53

-

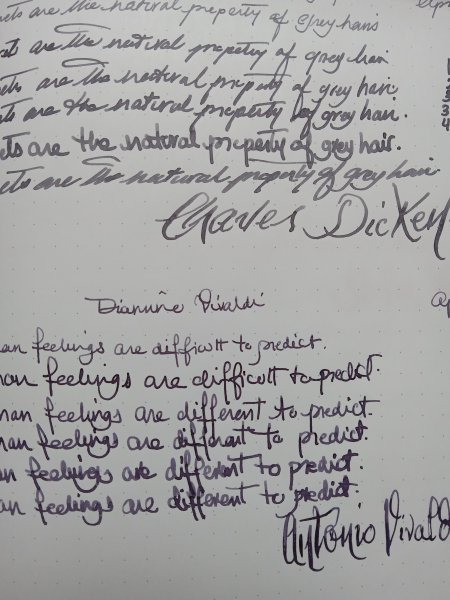

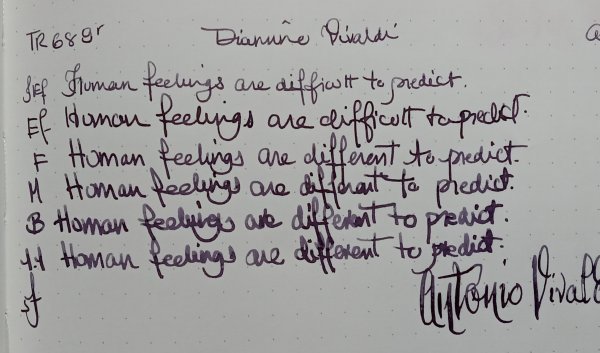

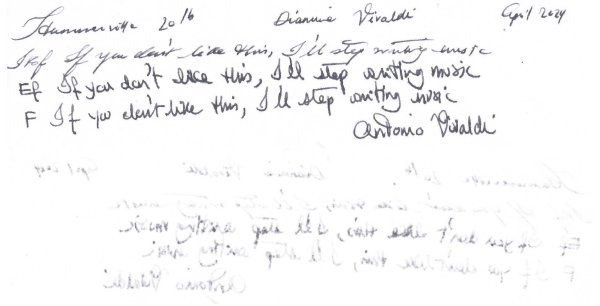

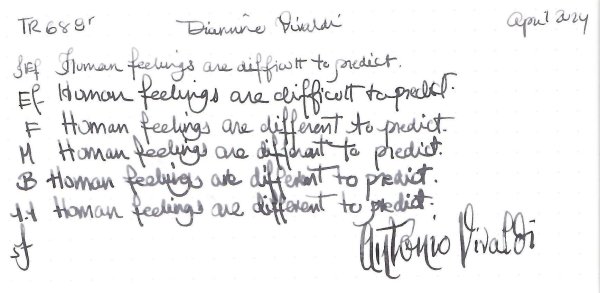

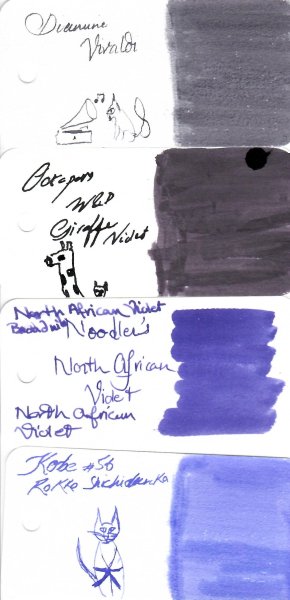

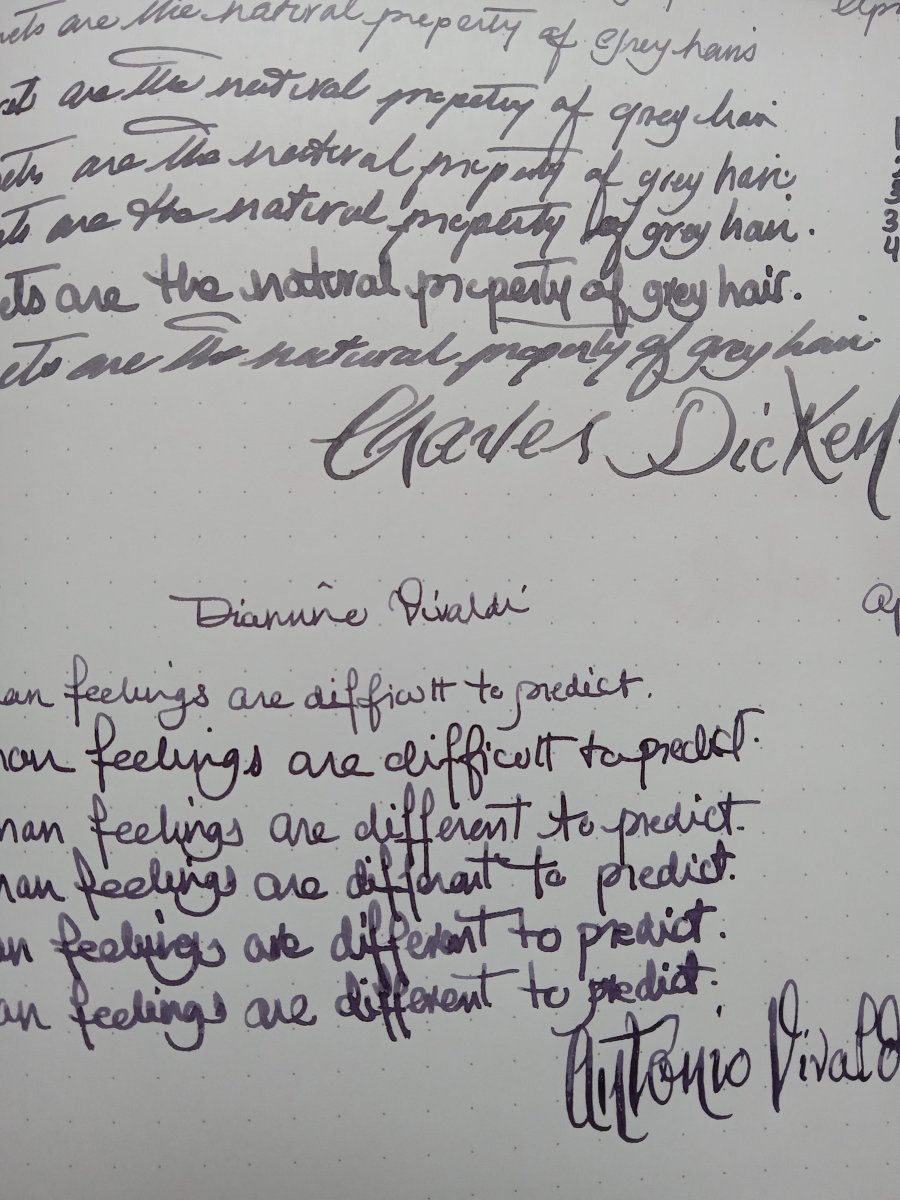

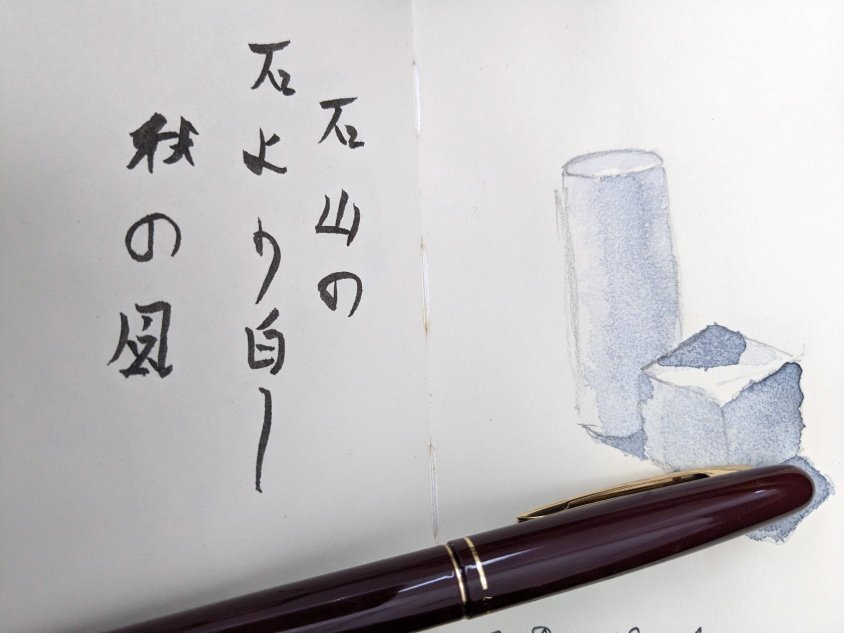

txomsy's quotes

- By txomsy,

- 0

- 5

- 82

-

Ne

- By Penguincollector,

- 0

- 0

- 6

-

pen repair

- By lionelc,

- 0

- 0

- 1

-

Misfit’s 4th album of Pens etc

- By Misfit,

- 99

-

.thumb.jpg.f07fa8de82f3c2bce9737ae64fbca314.jpg)

desaturated.thumb.gif.5cb70ef1e977aa313d11eea3616aba7d.gif)

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now