Columbus Extra 140...anyone Restored One?

-

Forum Statistics

352.3k

Total Topics4.6m

Total Posts -

Member Statistics

125,508

Total Members2,359

Most OnlineNewest Member

S Green

Joined -

Images

-

Albums

-

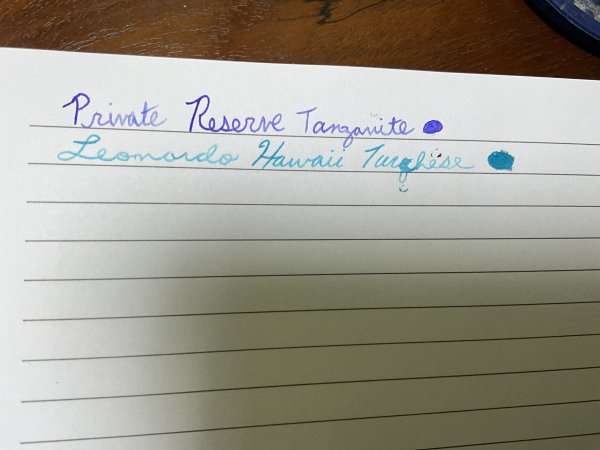

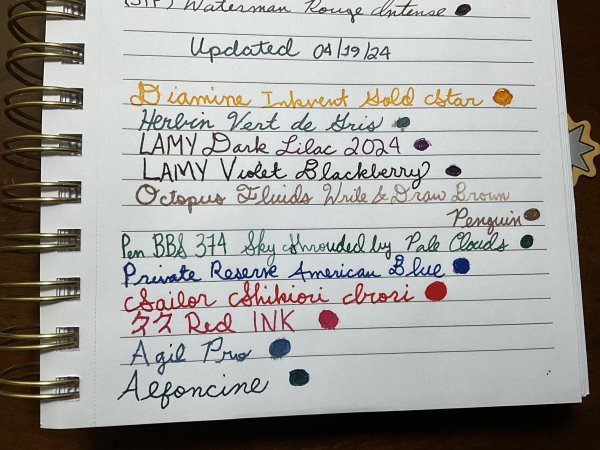

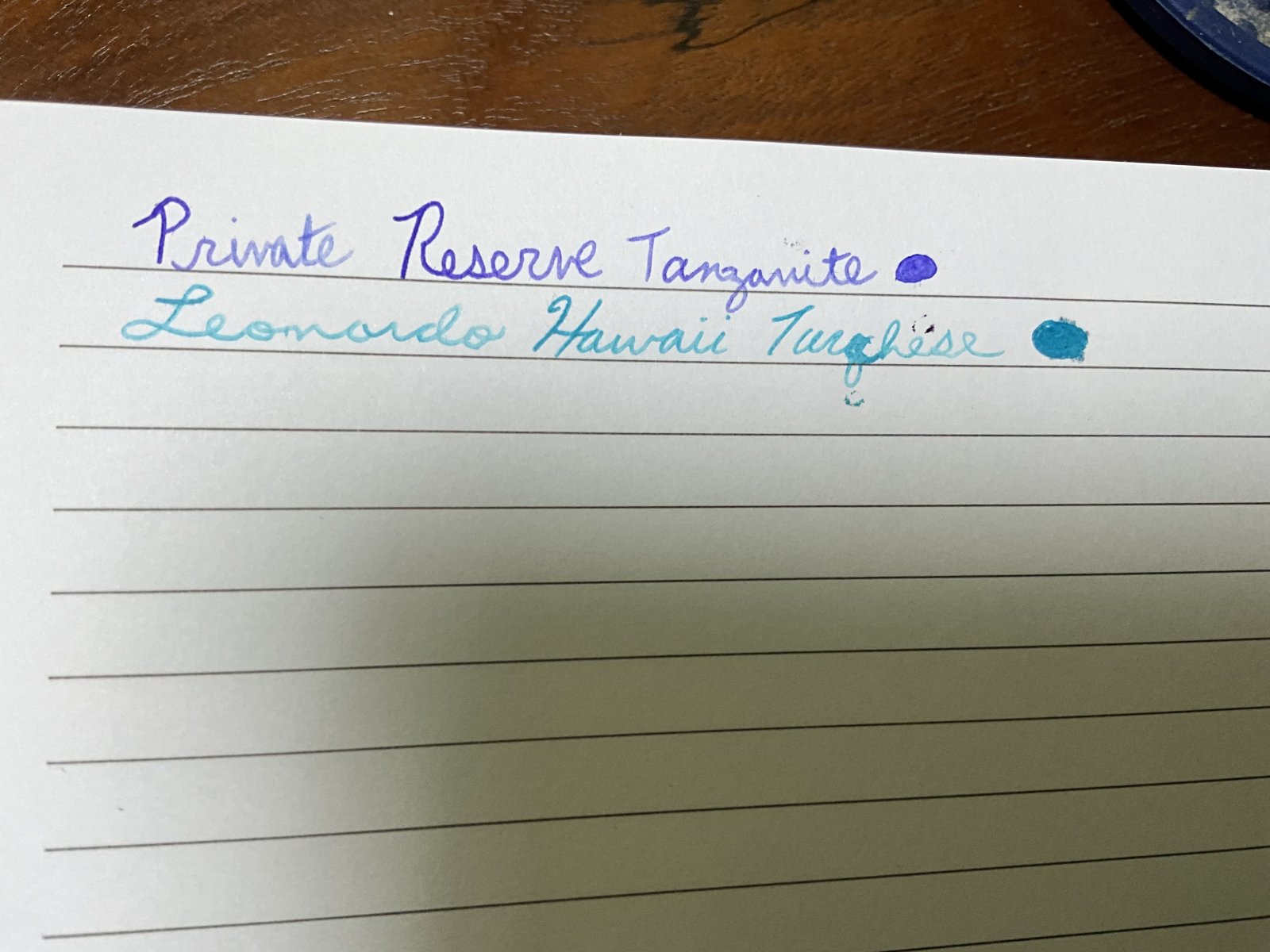

Sample Inkventory

- By Penguincollector,

- 0

- 0

- 9

-

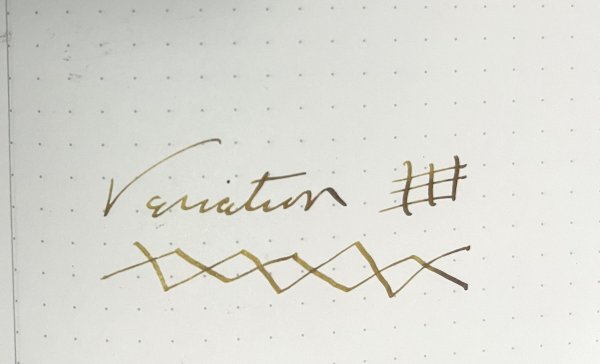

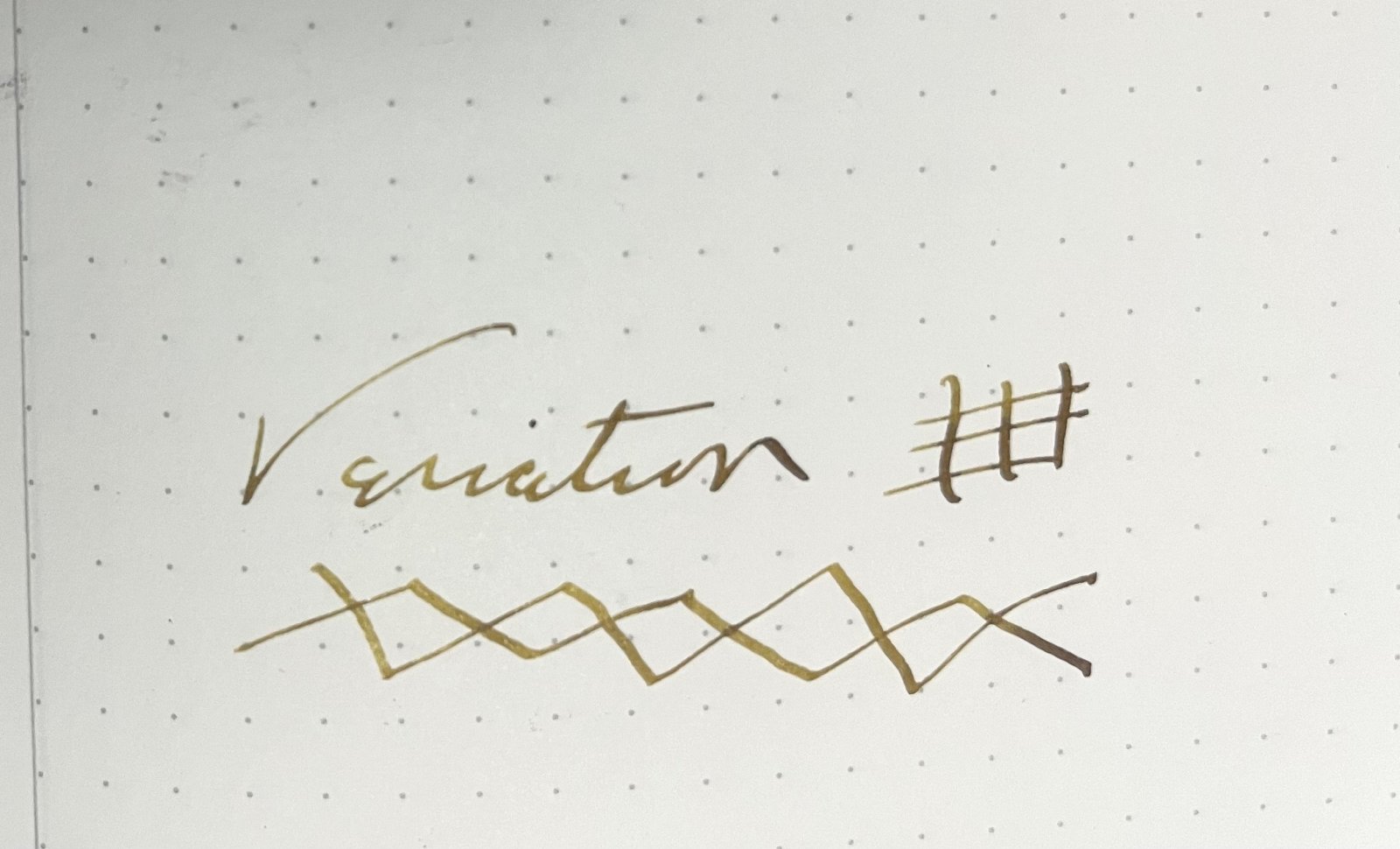

gweimer1 gallery

- By gweimer1,

- 0

- 0

- 2

-

karmachanic 1

- By Karmachanic,

- 0

- 0

- 29

-

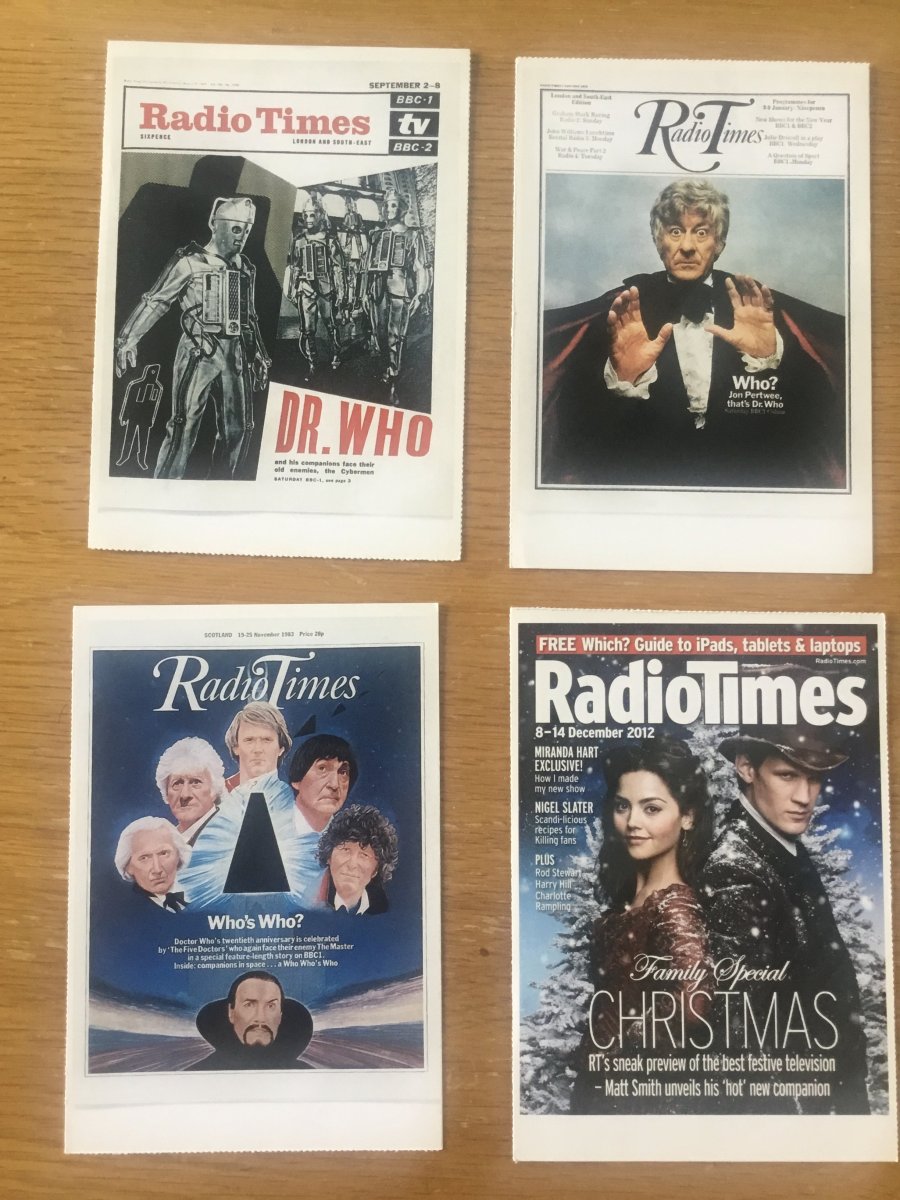

Mercian’s Miscellany

- By Mercian,

- 0

- 14

- 21

-

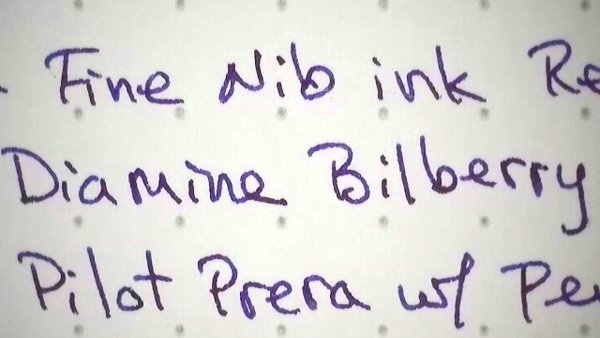

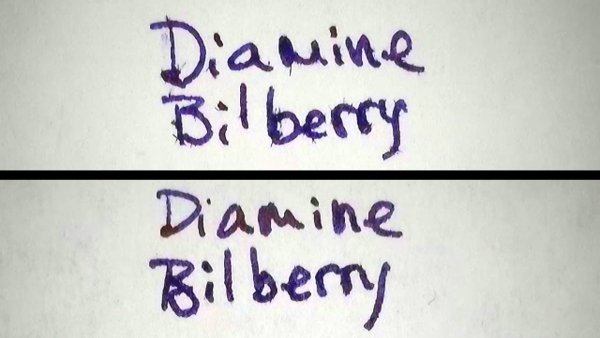

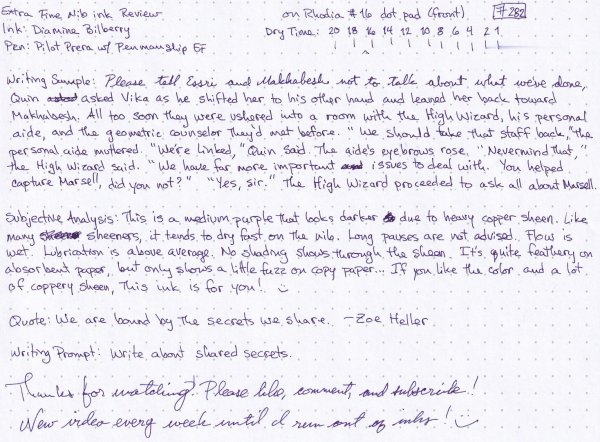

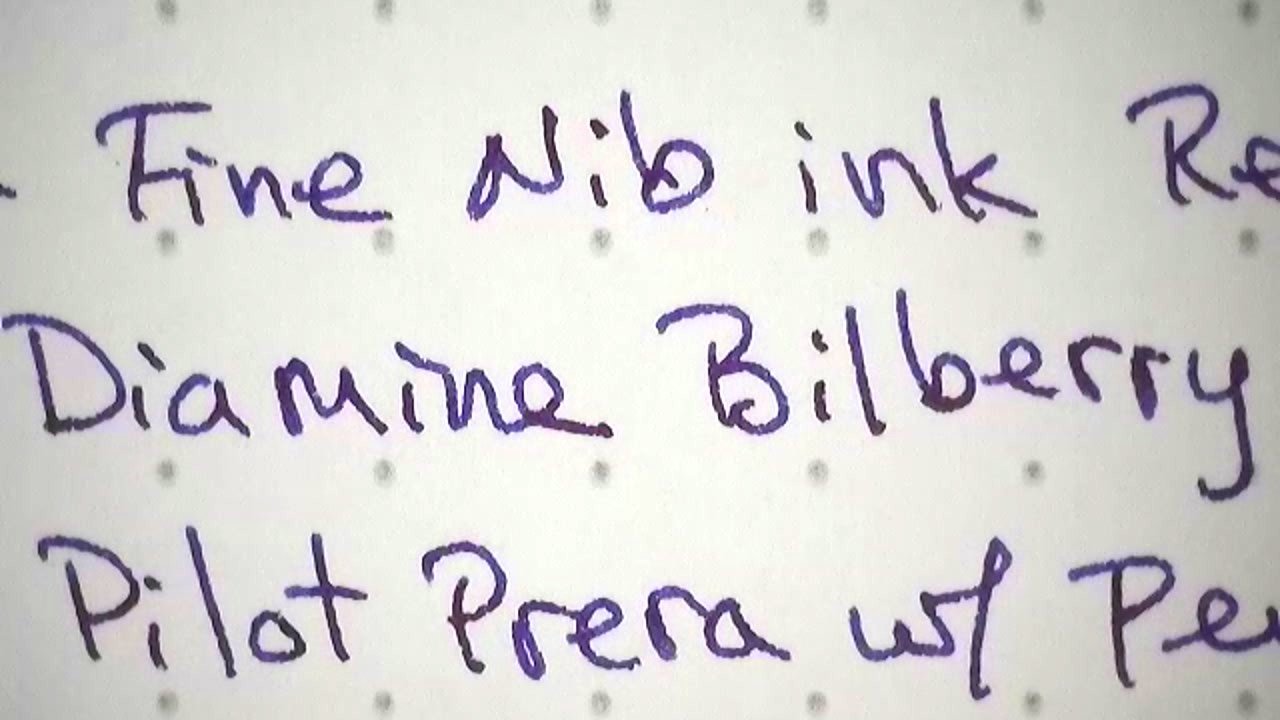

Extra Fine Nib Ink Reviews (17 of n)

- By LizEF,

- 0

- 24

- 24

-

.thumb.jpg.f07fa8de82f3c2bce9737ae64fbca314.jpg)

desaturated.thumb.gif.5cb70ef1e977aa313d11eea3616aba7d.gif)

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now