Sheaffer Vac-Fill Packing Units

-

Forum Statistics

352.2k

Total Topics4.6m

Total Posts -

Member Statistics

125,466

Total Members2,078

Most OnlineNewest Member

legin79

Joined -

Images

-

Albums

-

Old fountain pens

- By shalitha33,

- 0

- 0

- 20

-

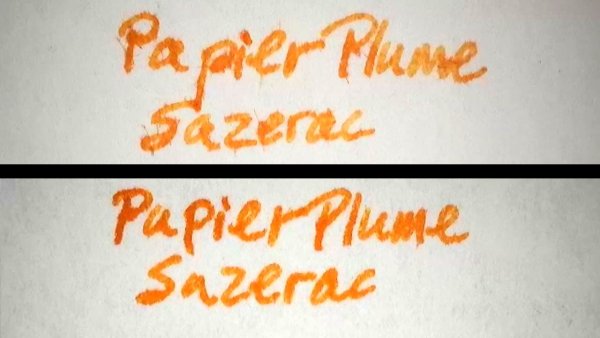

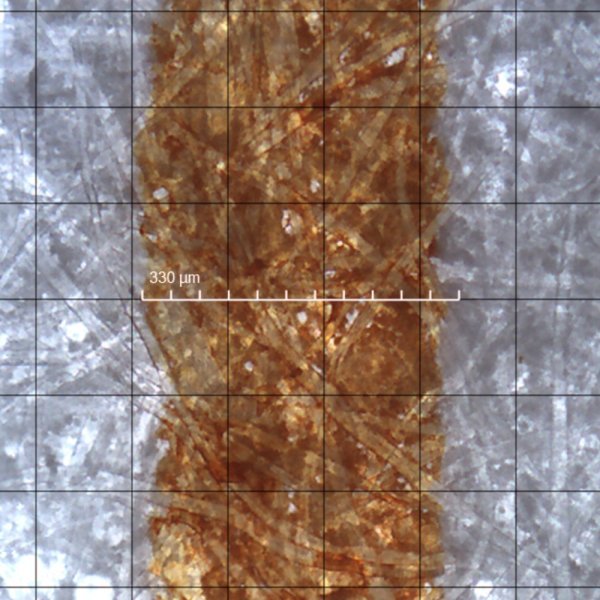

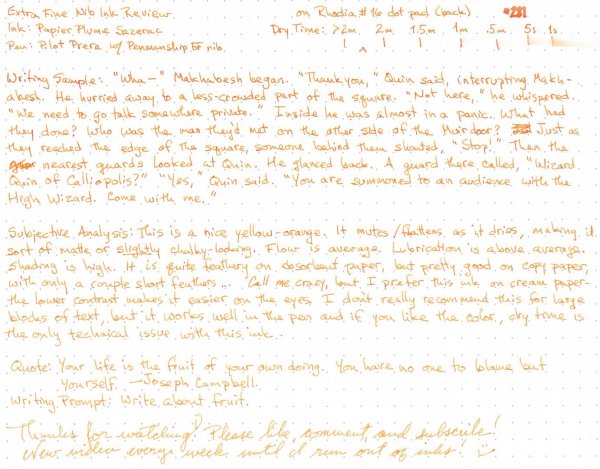

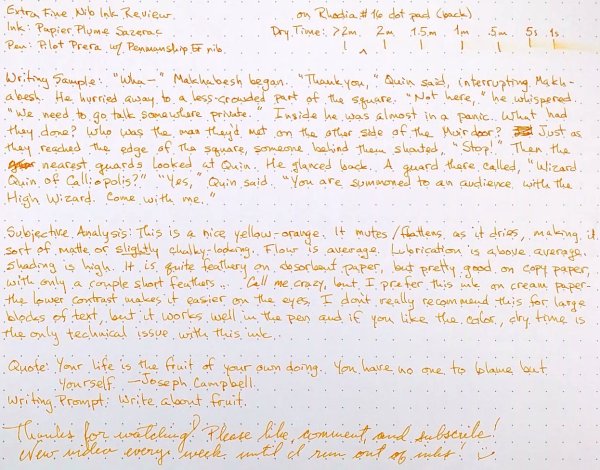

Extra Fine Nib Ink Reviews (17 of n)

- By LizEF,

- 0

- 19

- 19

-

more

- By AmandaW,

- 3

- 3

- 63

-

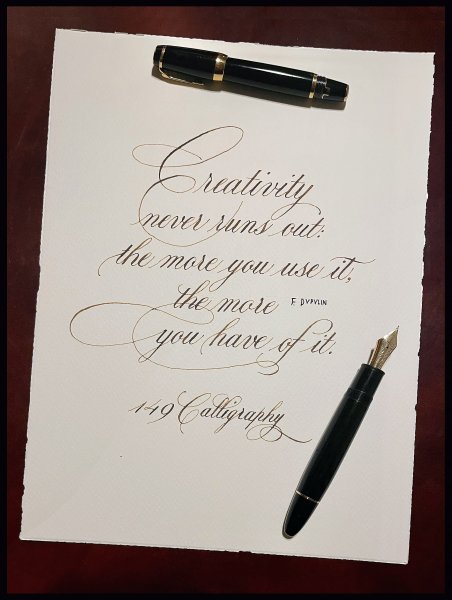

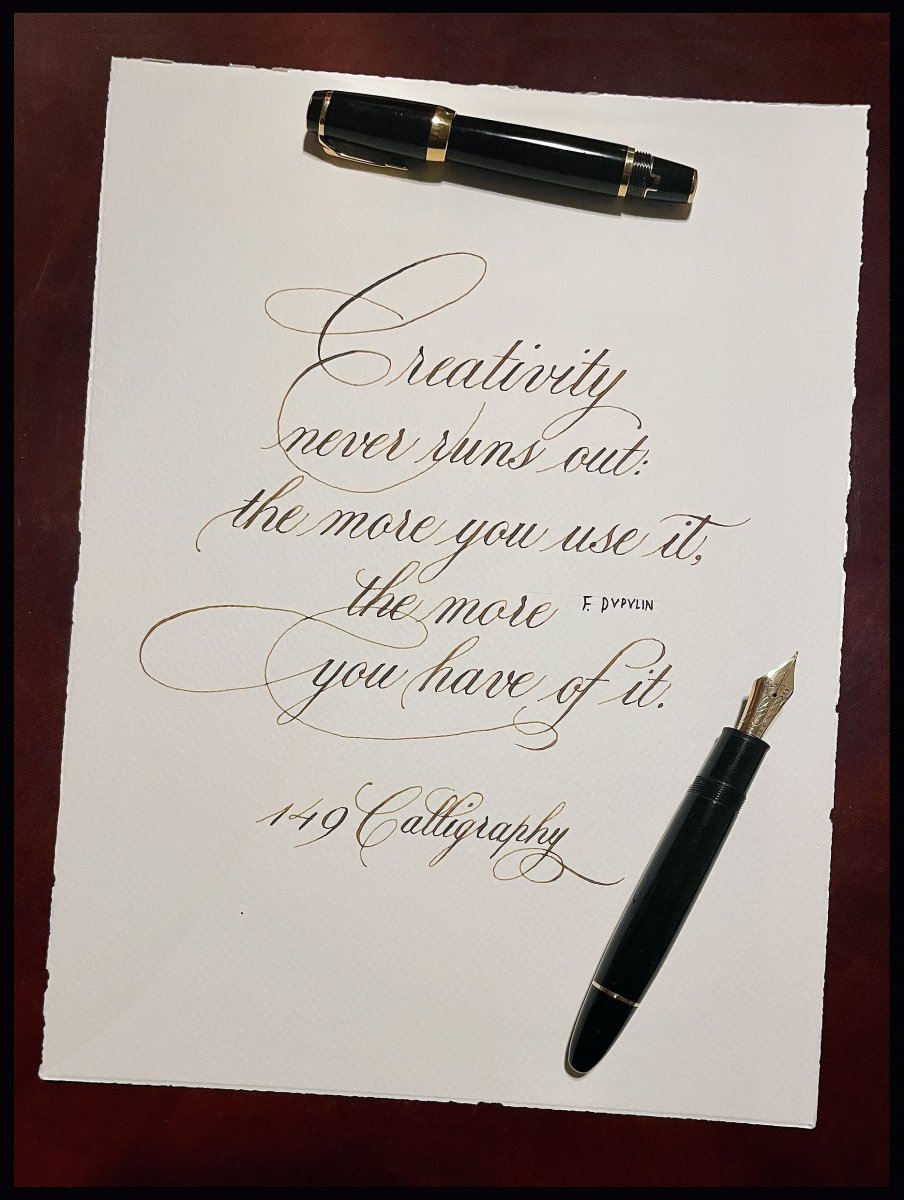

Icones Pupulinianae V

- By fpupulin,

- 0

- 1

- 31

-

OCArt #2

- By OCArt,

- 0

- 1

- 15

-

.thumb.jpg.f07fa8de82f3c2bce9737ae64fbca314.jpg)

desaturated.thumb.gif.5cb70ef1e977aa313d11eea3616aba7d.gif)

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now