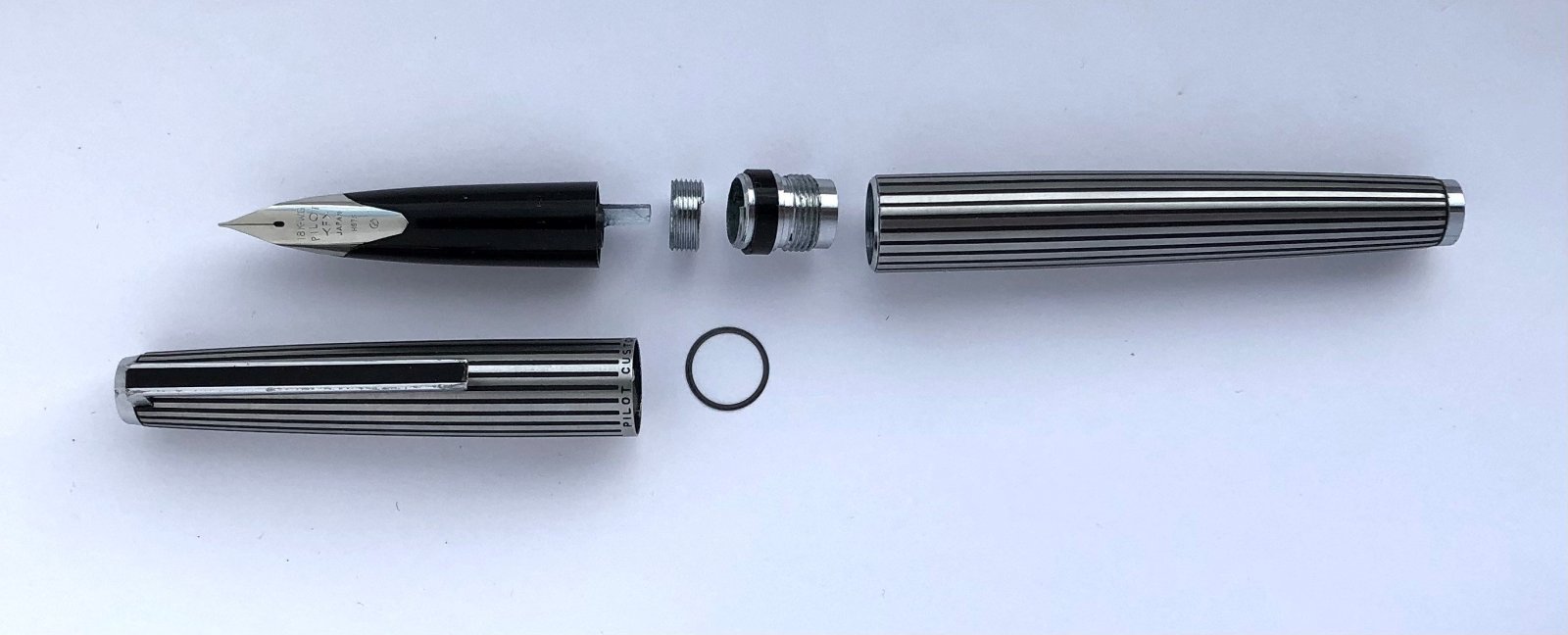

M800 M1000 Piston Filler Unit: Under The Hood.

-

Forum Statistics

352.2k

Total Topics4.6m

Total Posts -

Member Statistics

125,474

Total Members2,078

Most OnlineNewest Member

jhlion

Joined -

Images

-

Albums

-

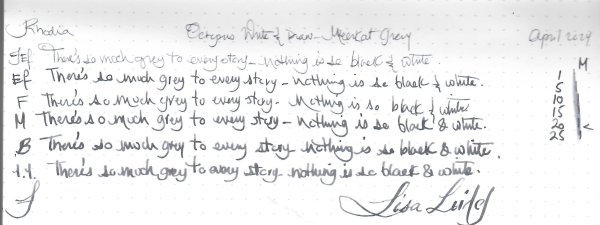

OCArt #2

- By OCArt,

- 0

- 1

- 16

-

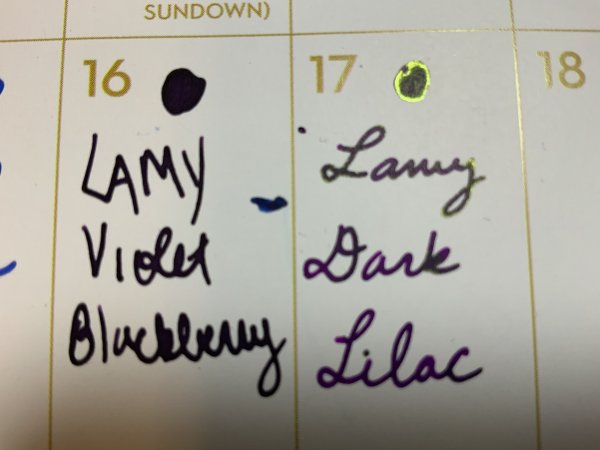

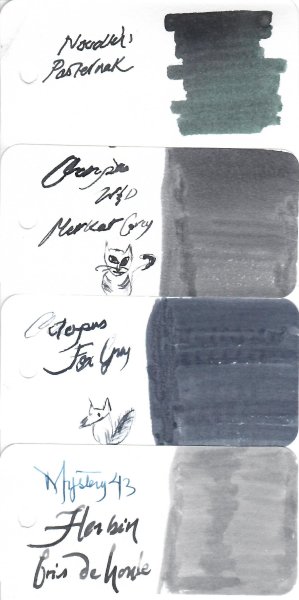

Ink

- By Penguincollector,

- 0

- 0

- 5

-

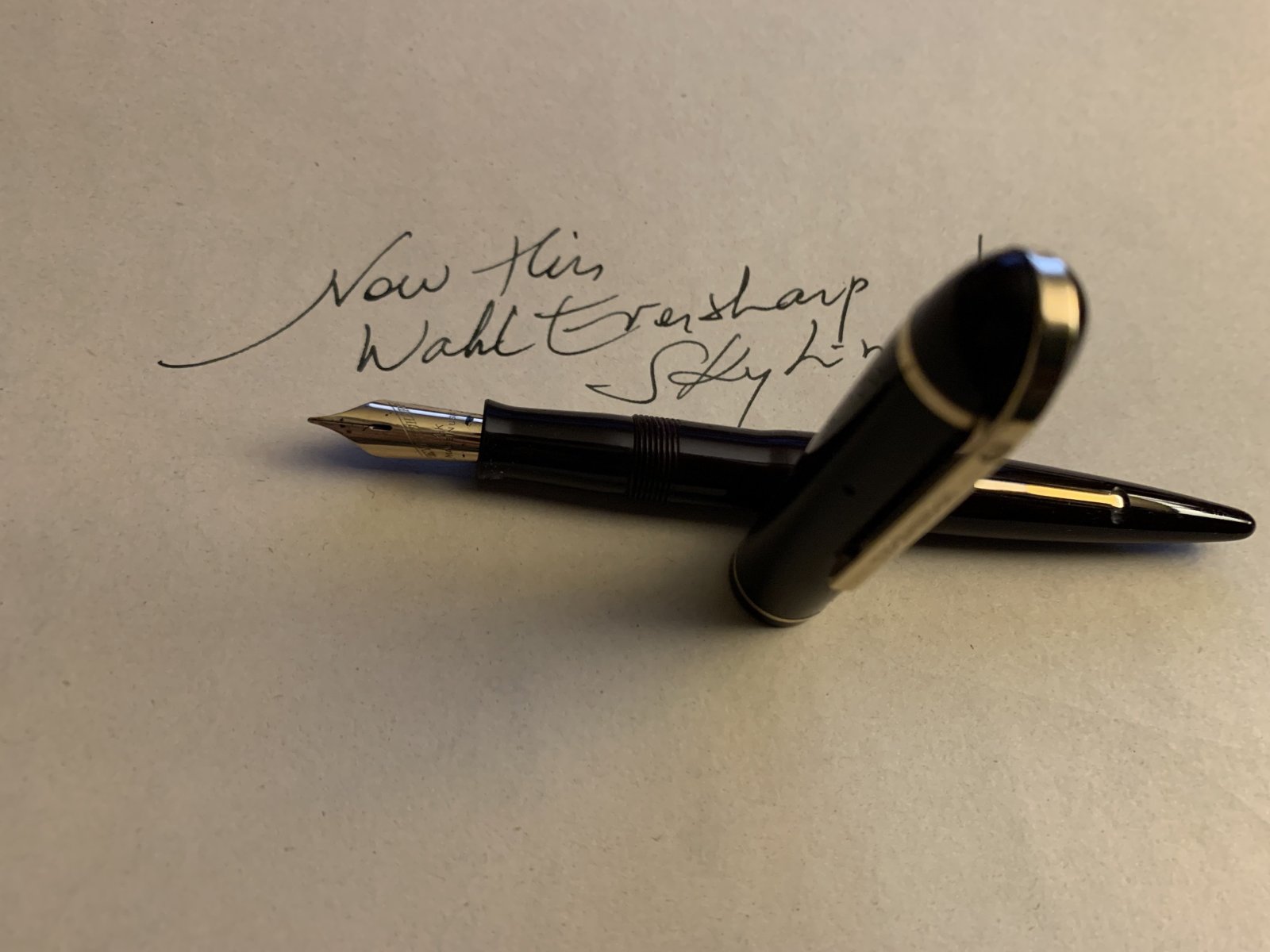

Nethermark Osmia

- By Nethermark,

- 0

- 0

- 26

-

March- April -2024

- By yazeh,

- 0

- 0

- 43

-

For The Posts

- By ZeroDukE,

- 96

-

.thumb.jpg.f07fa8de82f3c2bce9737ae64fbca314.jpg)

desaturated.thumb.gif.5cb70ef1e977aa313d11eea3616aba7d.gif)

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now